Siemens Energy: Analysis of environmentally assisted crack propagation in turbine blade superalloy

Siemens Energy have used the advanced microscopy facilities at the Bridge, including focussed ion beam milling and the FEG-SEM, and high-resolution scanning/transmission electron microscopy (S/TEM) with EDX elemental analysis to further understand how microcracks grow in CMSX-4 test samples thermally exposed to environmentally assisted crack test conditions.

Download Exemplar Study

Siemens Energy: Analysis of environmentally assisted crack propagation in turbine blade superalloy

BACKGROUND

Siemens Energy, a leading global energy technology company, operates a state-of-the-art manufacturing facility in Lincoln, UK and are a member of the Bridge, they specialise in the design and production of cutting-edge gas turbines renowned for their exceptional performance.

Siemens Energy turbine blades are meticulously crafted from advanced single-crystal nickel-based superalloys like CMSX-4. This cutting-edge material boasts exceptional high-temperature strength, exceptional creep resistance, and a resistance to high temperature oxidation and hot corrosion – critical attributes for withstanding the rigorous demands of continuous operation.

Siemens Energy gas turbines are designed to operate 24/7, 365 days a year, providing reliable power generation. These turbines operate in extremely demanding environments characterised by high temperatures, intense mechanical stresses, and elevated pressures, while simultaneously enduring exposure to a variety of chemical agents used as fuels, all in the presence of oxygen.

Understanding the potential degradation mechanisms within this challenging environment is paramount. By meticulously analysing these factors, Siemens Energy can continually innovate and extend the lifespan of their turbines, minimising costly downtime and ensuring maximum value for their customers.

APPROACH

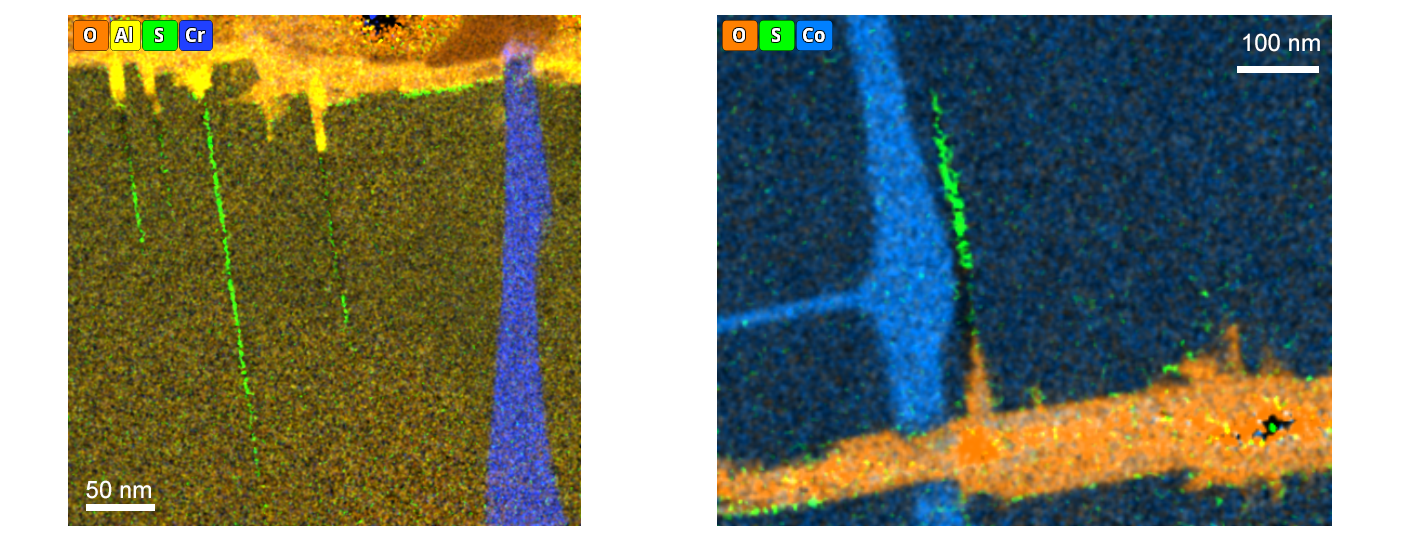

Siemens Energy have used the advanced microscopy facilities at the Bridge, including focussed ion beam milling and the FEG-SEM, and high-resolution scanning/transmission electron microscopy (S/TEM) with EDX elemental analysis to further understand how microcracks grow in CMSX-4 test samples thermally exposed to environmentally assisted crack test conditions.

SUMMARY

The combination of FIB-SEM and EDX-STEM is shown to be a very powerful technique to aid characterisation of degradation mechanisms in metals such as this superalloy. It allows the extraction of samples for ultra-high resolution analysis at exactly the desired location on a specimen.

Using the combination of S/TEM with EDX allows us to detect and locate tiny amounts of a wide range of elements, helping to elucidate the diffusion paths of corrosive elements. The data obtained here supports the suggested mechanism of sulphur-induced environmentally assisted cracking.

Knowledge of the mechanism allows Siemens Energy to improve products, and understand operating conditions which can potentially affect turbine blade lifetime – for example, using sulphur-rich fuels.